FlexiTrim Universal Molding system from Meteor Creative is the most user-friendly molding available to the Auto Glass Technician. It is planetary wound to eliminate kinks, twists, rolls, and length stabilized to remove shrinking and stretching. Creative uses the same OEM materials in FlexiTrim as the parts we supply to our OEM customers. These materials guarantee durability and highest quality and the look your customers desire for years after application.

Advantages:

- Non-Metallic Stabilizer – Only FlexiTrim offers the installer Meteor Creative’s patented non-metallic stabilizer. This unique stabilizer maintains the length of the FlexiTrim molding during the life of service. No shrinking up the A-pillars or rolling in the corners, which are common failures of windshield molding systems. For any universal molding to be truly universal and user-friendly it must be flexible. Once you bend a metallic stabilizer, the stabilizer tends to stay bent. This can cause a wavy appearance and a dissatisfied customer.

- Anti-noise – Only FlexiTrim Universal Moldings use anti-noise materials co-extruded on surfaces that contact sheet metal. This unique material virtually eliminates the noise created by the windshield molding system. This material is co-extruded into the FlexiTrim molding, eliminating the mess that topically applied materials create.

- OEM Approved PVC – FlexiTrim utilizes only 100% virgin PVC which meets or exceeds the automotive original equipment specifications for EXTERIOR trim applications. FlexiTrim moldings are never manufactured using regrind, off-spec, or lead-contaminated materials.

- OEM Approved Tape – Black tape blends in with the black paint used on windshields and back glass. OEM tape with high bond strength and performance in heat and cold.

- Patented Tear Away Alignment – This unique feature allows the auto glass technician to align the molding to the glass edge easily. After applying the molding the feature is then quickly removed by peeling it away from the molding, creating a clean uniform look.

- Butyl – FlexiTrim uses OEM approved butyl adhesive as an assembly aid to help hold the FlexiTrim molding on the glass until it is installed into the vehicle. This allows for the installer to apply the molding at the job site or in the shop prior to leaving for the job site.

- Multiple Profiles – There is a FlexiTrim molding to fit most installations. Choose from one of our 12 profiles to match the OEM molding or dress up a vehicle with our BriteFlex, Feature Line, U-Lip versions.

Interested customers have to buy directly from our distributors, but please feel free to contact us with all your technical questions.

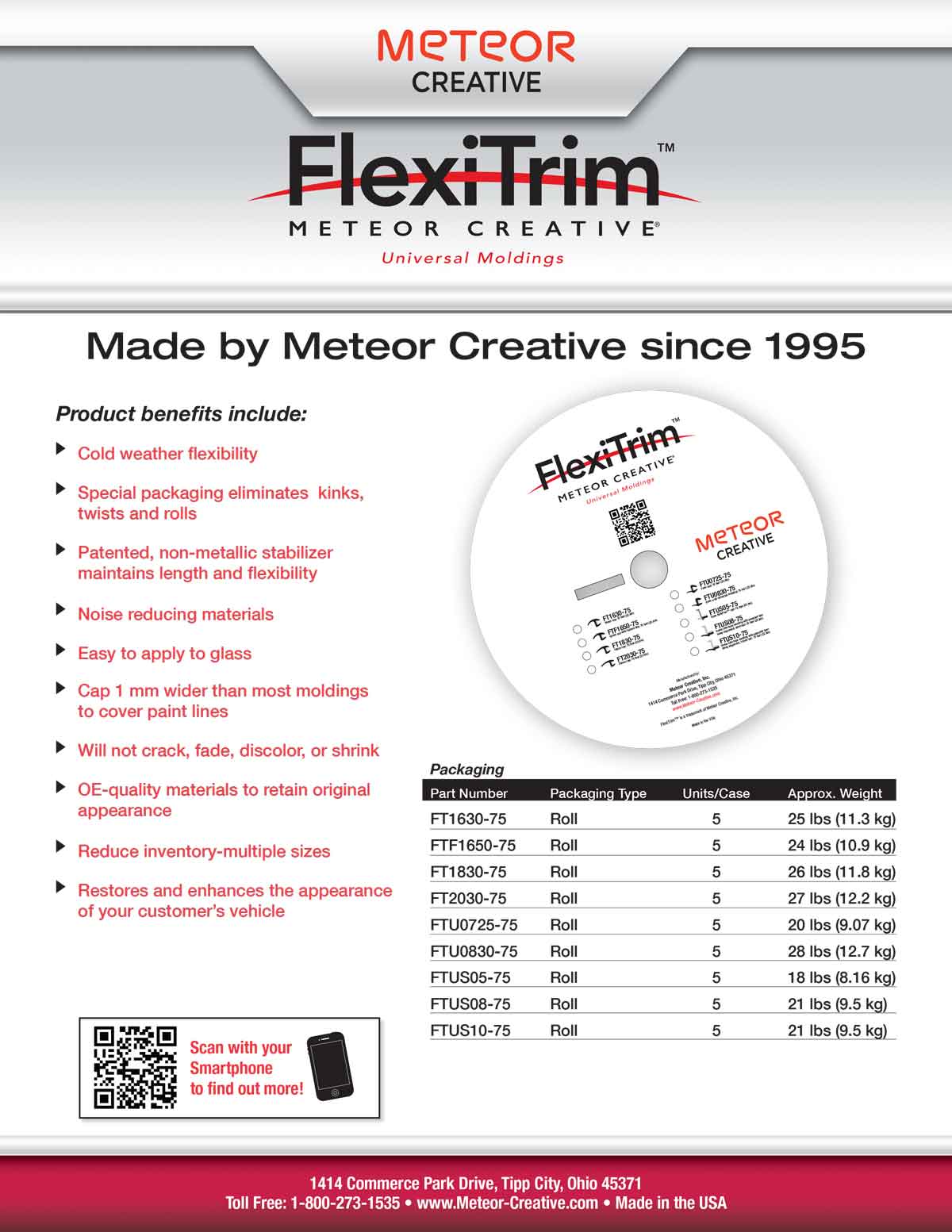

FLEXITRIM PARTS